Specifications

Press Range

- 25-600 Tons

- * Over 35 Presses between both the Southwest & Corporate Locations

Press Bed Sizes

- 144” x 72”

- 48” Servo Feed Capability with 12,000lb. Capacity

Minimum Part Thickness

- 0.005 Inches

Maximum Part Thickness

- 0.500 Inches

Materials

- Pre-Finished Materials

- Pre-Plated

- HRS/CRS

- HSLA

- Hot Rolled

- Cold Rolled

- Stainless Steel (200 or 400 Series)

- Galvanized

- Galvannealed

- Aluminum

- Brass

- Copper

- Silver

- Red Metals

- *More Materials Available Upon Request

Tolerances

We will meet your requirements, and if we think we cannot we will alert you to why

Quality Systems Include

- AIAG PPAP

- 8D

- Lean

- Six Sigma

Inspection Procedures

- In-Production Quality Inspection

- 1st Piece Quality Inspection

- Final Quality Inspection

- PPAP- Up to Level 3 (Automotive)

- First Article Quality Inspection

- FMEA (First Mode & Effects Analysis)

- Poka- Yoke

- MSA (Measurement System Analysis)

- Capability Analysis

- PSW Approvals

Quality Control Certifications

- ISO/TS 16949:2009

- RoHS Compliant (Restriction of Hazardous Substances)

- ASTM (American Society for Testing and Materials)

- UL

- CSA/cUL

Additional Value Add Services

- ESI (Early Supplier Involvement with our Expert Engineering Staff)

- Powder Coating

- DFM (Design For Manufacturability)

- In-House Tooling

- CNC Machining

- Drilling

- Bending

- Tapping

- Outside Finishing Such as: Plating, Painting, & Heat Treating

- Welding

- Riveting

- De-Burring

- Secondary Press Work

- Hand Finishing

- Sub & Complete Assemblies

- Specialty Packaging & Quality Control Preparations

Production Method

- Progressive Tooling

- In Die Insertion

- In Die Tapping

- In Die Labeling

- Compound/Secondary Tooling

Production Capabilities

- Miniature, Small, Medium, Large Sized Parts

- Prototypes

- Pilot Builds

- Medium to High Volume Production

Have a Project in Mind? Contact Us!

Please leave us the following information, and we will promptly reach out to you regarding your request.

About Us

Global Leader in Precisiton Sheet Metal Fabrication, CNC Machinining, Contract Manufacturing, Powder Coating, Value-addServices

Years of

Excellence

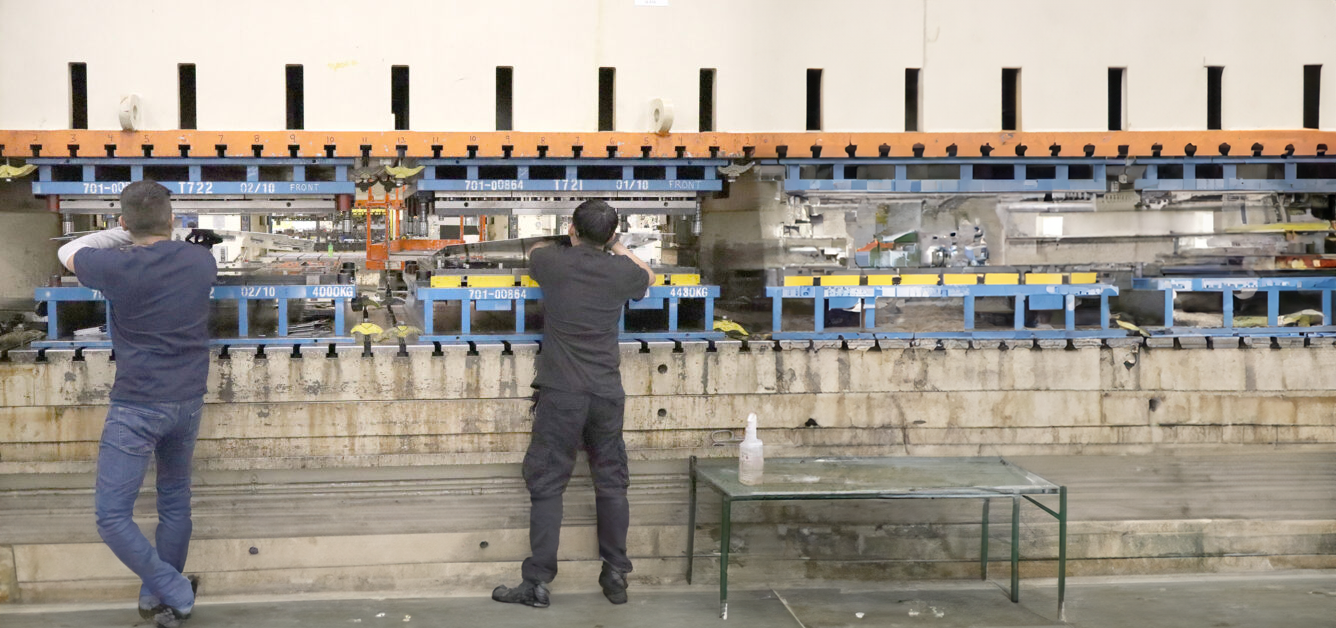

State-of-the-Art Facilities

Heavy Presses & Stamping Machines

Square Feet

Under Roof

World-Class Certifications

Who We Serve

Larsen Manufacturing proudly serves a diverse group of customers spanning thousands of different applications.

Industrial

We service a wide range of industrial applications…

Automotive

We make a wide variety of automotive parts…

Medical

We make parts for a variety of medical equipment…

Energy

We service different applications within the energy sector…

Electronics

We service many applications of electronics